Synthesis and derived properties of rare‐earth‐doped diffusion coatings on alloy materials for extreme environments (SYNPROCOAT)

Project Overview

Based on the cooperation program of the France-Poland strategic partnership about energy and environment, theoverall goal of SYNPROCOAT is to synthesize alternative eco-friendly and durable rare-earth-doped diffusion coatings on steels toensure extended lifetime of components under extreme hot corrosion conditions like those encountered in turbines of power plants(conventional and renewables). For the first time in the openliterature, the rare-earth-doped coatings will be synthesized from by-products of the industry andhomogeneously dispersed in the coating matrix on conventional power plant steels. The corrosion resistance will beassessed by comparing different corrosion atmospheres impact and biomass atmospheres (fireside corrosion). The derived thermal conductivity and adhesion of the coatings and of the corrosion products will also be determined, in this project besides of slurry coatings with industry recovered rare elements as well diffusion coatings based on pack cementation process will be investigated and comparable. The diffusion pack coatings will be doped with rare elements (RE): cerium (Ce), yttrium (Y) and lanthanum (La), the coatings will be deposited on the: T24, T/P92, Incoloy 800HT, AISI 309S. steels. The materials will be exposed at high temperatures (> 500 oC ) and analyses using Scanning Electron Microscope (SEM), Energy dispersive X-Ray Spectrometry (EDS) and X-Ray Diffractometer (XRD) will carried out. The project is divided into 5 different objectives:

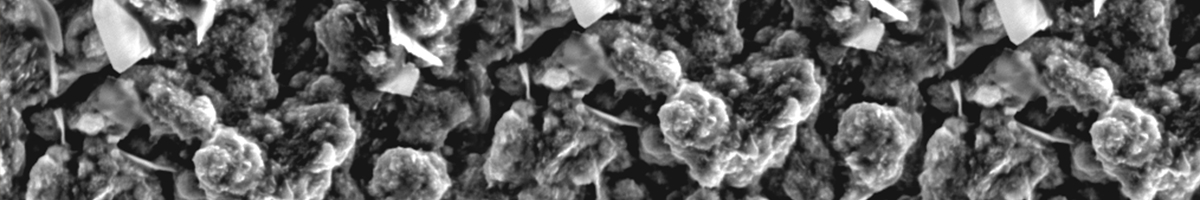

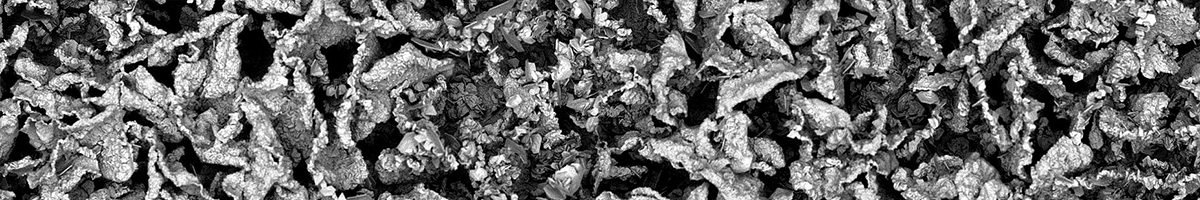

OBJECTIVE 1: Slurry Al diffusion coatings with rare-earth elements

The originality lies here on the use of the recycled RE-containing aqueous solutions as the basis to prepare the suspension (slurry) towhich Al microparticles will be added, sprayed on the steels’ surface and finally annealed. The fabrication method of thesecoatings using recycled RE-products was never reported.The main scientific challenges are to understand how these newcoatings form. Indeed, the self-propagating synthesis occurring upon reaction of Al and Fe induce a local increase of temperaturethat ensure a quick formation of the coatings. Furthermore, intermediate perovskite (REAlO3)compounds could form by reaction of RE, Al and the very few ppm of O2 in the atmosphere that can hurdle diffusionand the presence of these oxides could buffer the heat release so thatthe reaction can be limited or even stopped.

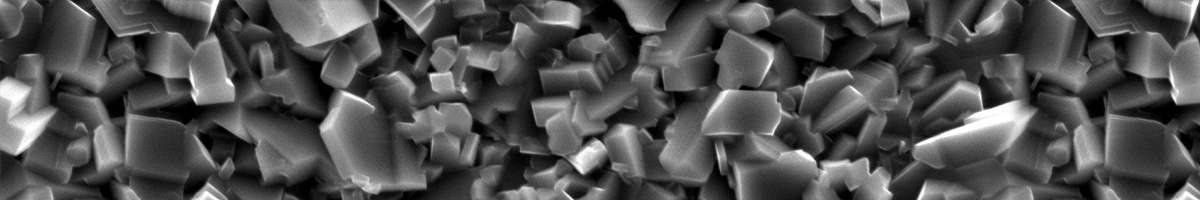

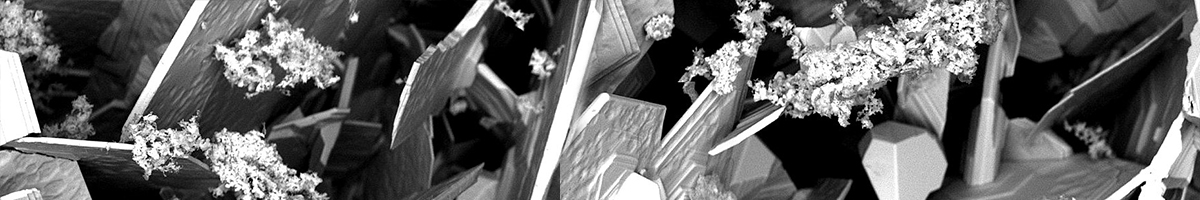

OBJECTIVE 2: Pack cemented Al diffusion coatings with rare-earth elements

The mechanisms in pack cementation that lead RE to segregate at active surfaces/grain boundaries and to limit the thickness ofthe coating are not clearly elucidated. Therefore, the scientific challenge will be relatedto understand how new homogeneous coatings are made by pack cementation. The specificcompositions of the packs (donor, activator, filler) and the temperature/times will be assessed based on thermodynamiccalculations. One original approach will consist in comparing the effect of the type (cerium, lanthanum) and nature (metal or oxide)on the final microstructures and chemical distribution in the Al-diffusion coating.

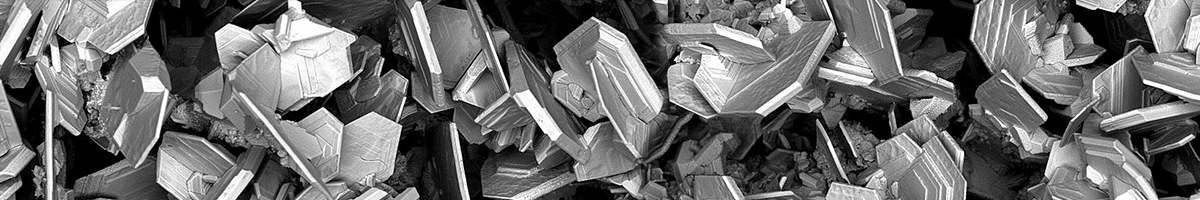

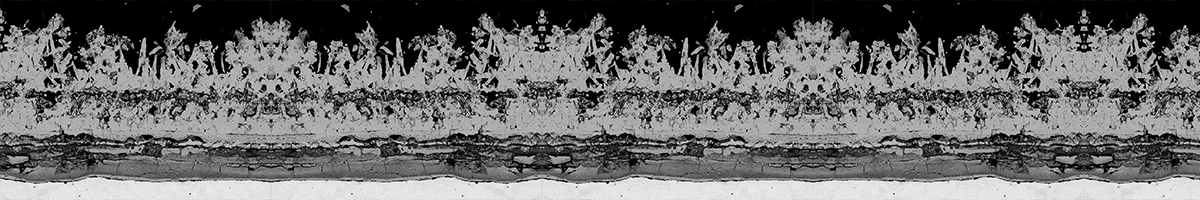

OBJECTIVE 3: Steam oxidation

Steam oxidation is the main degradation mechanism inside the heat exchanger tubes. Therefore, it is essential to perform suchtest (up to 2000 hours, at 650 oC). The pack cemented (Poland) and the slurry coated (France) samples will be carried out inPOLAND by weight variations and analyses every 250 h. This will allow toassess the kinetics of oxidation, hence to determine a predictive law of behaviour.

OBJECTIVE 4: Fireside corrosion

Ascertain the firesidemechanisms in the presence of oxyfuel and biomass contaminants on the new SYNPROCOAT coatings (slurry and packcementation), which has been never proposed in the open literature. One very original approach will be to assess the Rapp-Goto

ratio on the solubility of the oxides in the molten salts andgas atmospheres (H2S) given that the recycled RE-doped coatings will contain trivalent (e.g. La3+) and tetravalent species (Ce4+)and different contents (up to 1.5 wt.%). This will require to isolate first the role of each impurity salt in simple air and argonatmospheres to determine the activities and partial pressures of the corrosive species in mixed biomass salts without gas and with 0.25%H2S-Ar and 20%CO2-Ar gas.

OBJECTIVE 5: Thermophysical and adhesion

The corrosion species should lower the thermal conductivity in the as-deposited and corroded conditions, this issue must be investigated. Furthermore, this effect has never been reported in the open literature. The approach ofinvestigation will follow the isolation of each contributing element (substrate, coating) and their combination (coated substrate,corroded substrate and corroded coated substrate). In this objective, the aim obeys determining the adhesion of the coatingsand the corrosion products by thermal cycling typical for the power plant to respond to electricity demands. The correlation between microstructures development of the coatings before and after the corrosion tests with the stress andtemperatures will be established as well.